LiDAR Stockpile Volume Measurement Solutions - gantry, Overhead, & Bridge Crane Mounted LiDAR Sensors

how does Crane-mounted liDAR stockpile volume measurement system work

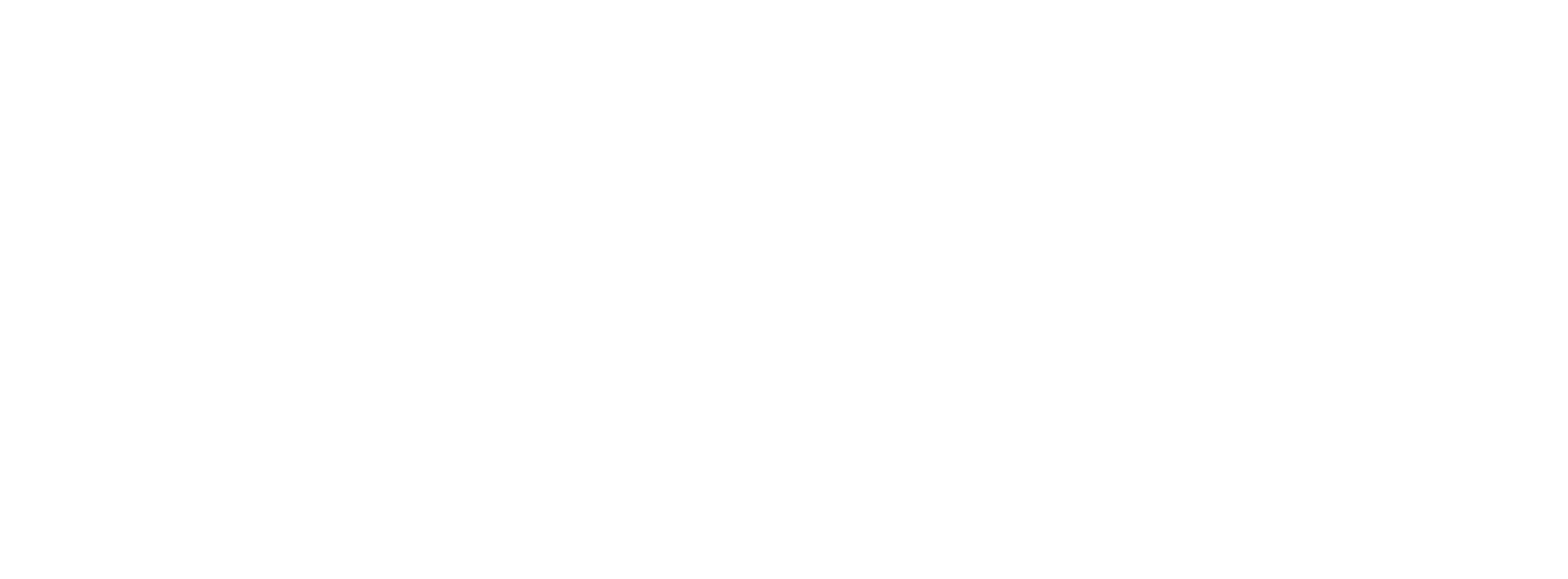

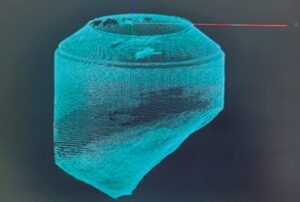

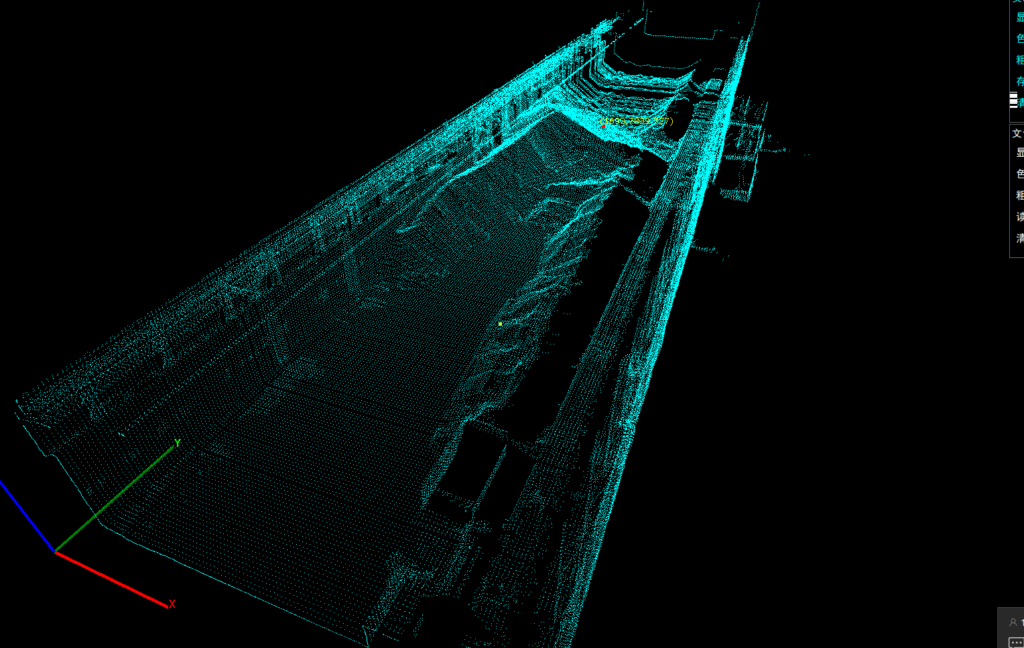

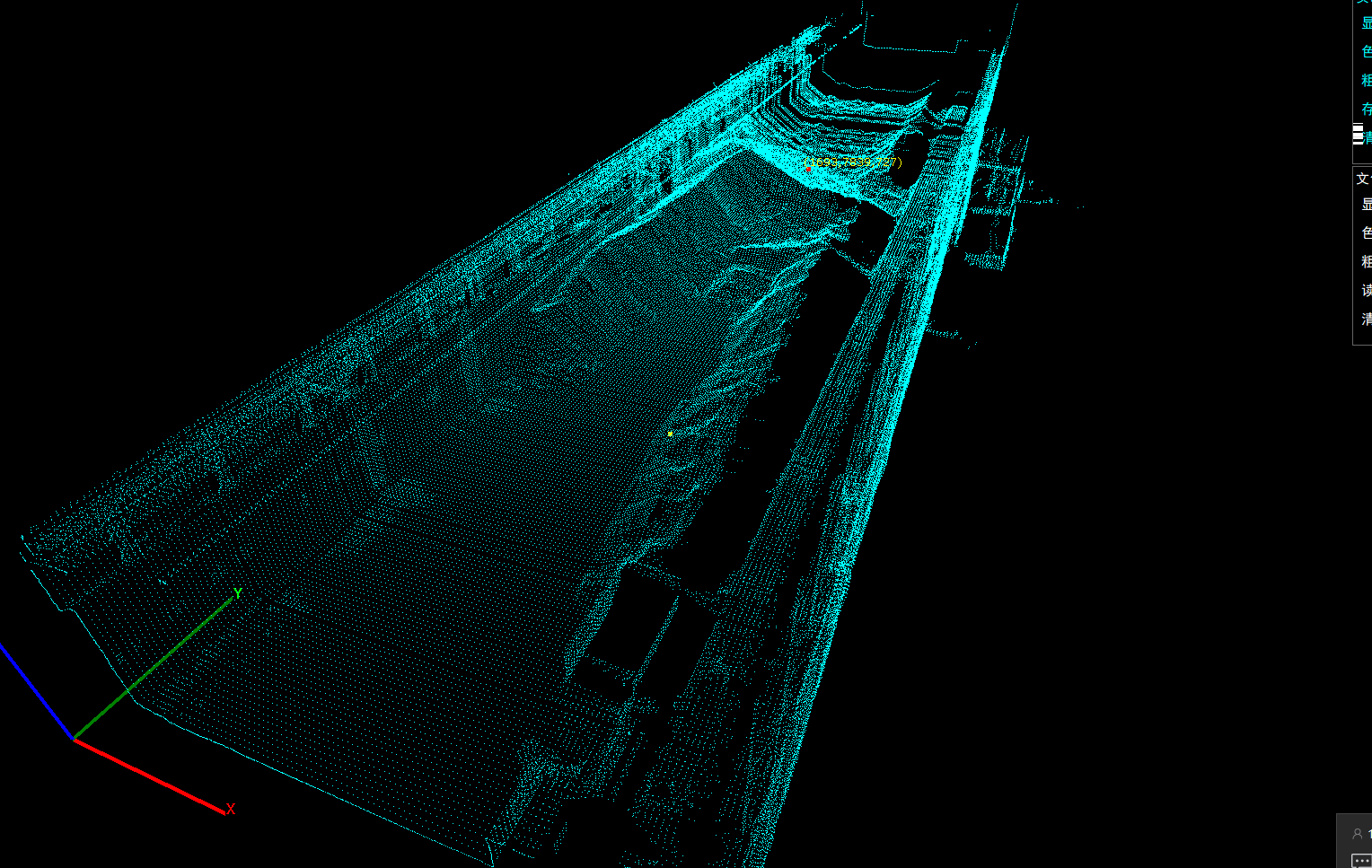

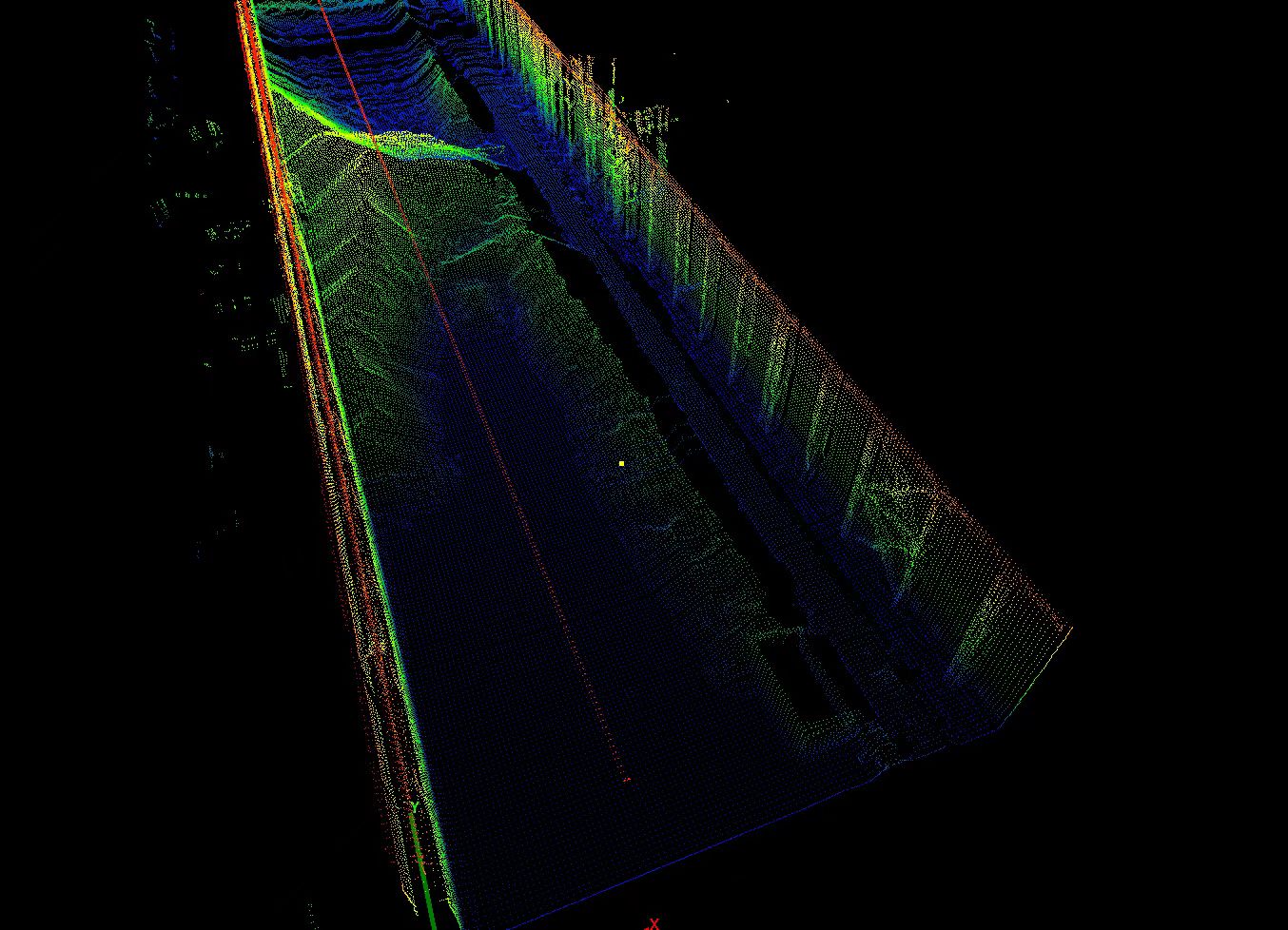

LiDAR, which stands for Light Detection and Ranging, determines mining material like coal stockpile volume by directing laser beams at the stockpile and measuring the time it takes for the beams to return. 2D LiDAR sensor is used for this solution, which can measure the cross section information of the stockpile, combined with the operation speed of gantry, overhead, or bridge crane. The system can create three-dimensional point cloud for one or more stockpile under the crane operation path. The volume of the stockpile can be calculated with great accuracy by analysing the point cloud data.

Cross sectional Data Collection: A 2D LiDAR sensor is used to scan the object surface to obtain point cloud data. It emits a laser beam and then receives the returned laser signals to generate 2D point cloud data representing the cross sectional shape of the object around the LiDAR.

Crane operation speed measurement: encoder is normally used for this purpose.

Date Preprocessing: It combines the cross sectional shape of the stockpile and the crane speed data to create a 3D point cloud data, it also includes denoising and smoothing. Denoising can eliminate some anomalies or noise interference, smoothing can smooth the data and remove unnecessary details.

- Surface Reconstruction: The discrete point cloud data is converted into a continuous surface model after reconstruction of preprocessed point cloud data. Frequently-used surface reconstruction algorithms include triangular mesh generation, voxel-based reconstruction, and other methods.

- Volume Calculation: Based on the reconstructed surface model, the volume of an irregular object is calculated using a volume calculation algorithm. The surface model can be divided into small voxels, by calculating the volume of which and adding them together, the total volume can be obtained. Volume calculations can also be realized through mathematical integration or numerical integration.

- Data Output: The volume results of irregular objects are output and displayed on a display, or transferred to other systems for further processing and analysis.

Except for measuring the stockpile volume, LiDAR point cloud data generated in different time can also be used to calculate the stockpile change as well as volume difference.

the benefits to use LiDAR equipment to measure stockpile volume

High Accuracy

LiDAR provides highly accurate measurements, which is essential for inventory management and resource allocation. The precision of LiDAR can help companies avoid costly mistakes and make more informed decisions.

High Efficiency

LiDAR is a fast and efficient method for measuring stockpile volumes. Traditional methods, such as manual surveying, can be time-consuming and labor-intensive. LiDAR, on the other hand, can quickly scan large stockpiles and provide accurate volume measurements in a fraction of the time.

Safety

LiDAR is a non-contact measurement method, which means it can be used to measure stockpile volumes without the need for personnel to physically access the stockpile. This is especially important for stockpiles of hazardous materials or in dangerous locations.

Versatility

LiDAR can be used to measure stockpiles of various sizes and shapes. It can also be used in different environments, from open-air stockpiles to enclosed storage facilities.

Data Analysis

The data collected by LiDAR can be easily integrated with other systems and used for further analysis. This can provide valuable insights into inventory management, resource allocation, and other aspects of operations.

Documentation

LiDAR point cloud processing software can be used to create detailed and accurate documentation of stockpile volumes. This can be useful for compliance with regulations, reporting to stakeholders, and other purposes.

Contact Us

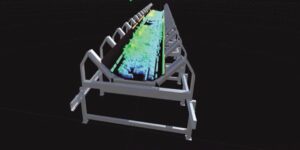

Crane Mounted LiDAR Volume Measurement Solutions - Site photos

The fixed LiDAR stockpile measurement system can be installed on the cranes either indoor or outdoor. Its installation location needs to be assessed according to the area to be covered underneath the crane.

In most case, only 1 LiDAR sensor is required on 1 crane, it can cover the whole area where the crane can move above, so it is very cost effective. However, the volume of the stockpiles can only be calculated after the crane is moved above the area, so its flexibility may be reduced.