Smart Mine LiDAR 3D Scanning Solution

With the advancement of modern surveying and mapping technology, the amount of data measured in mines is increasing, such as 3D mine mapping for open pit mining site and 3D modelling of mine tunnels, and the requirements for results are becoming more and more diverse. Digital mining management and efficient mining ecological monitoring have become inevitable requirements. Traditional remote sensing technology has the disadvantages of inability to obtain vertical structure, low accuracy and poor timeliness in mining surveying and mapping. 3D Scanning with LiDAR for mining industry has the characteristics of strong initiative, strong penetration, fast scanning speed and high precision, which can make up for the shortcomings of traditional remote sensing technology.

See our range of LiDAR products today.

Greenvalley International Co., Ltd. focuses on lidar and image fusion technology, and is proficient in lidar, UAV, SLAM, photogrammetry and other technologies to achieve accurate perception of three-dimensional space reality. Independent research and development of LiAir (airborne lidar 3D scanning system), LiBackpack (backpack lidar scanning system), LiPod (stand-mounted lidar scanning system), LiMobile (vehicle lidar scanning system) and other multi-platform high performance survey equipment for 3D laser scanning in mining sector, taking into account the general platform and industry-expanded point cloud data processing and analysis platform LiDAR360, aerial image stitching software LiMapper, LiDAR power line inspection LiPowerline, for power line inspection, forestry survey, topographic mapping, digital mining, disaster survey emergency, construction Provide core technical solutions in areas such as driverless high-precision maps. LiDAR Solutions is working closely with GVI to provide LiDAR service in mining industry in Australia and New Zealand, including 3D mine mapping solutions for open pit site, 3d laser scanning in mining section, equipment and service scanning mine tunnels, mining scanning software etc.

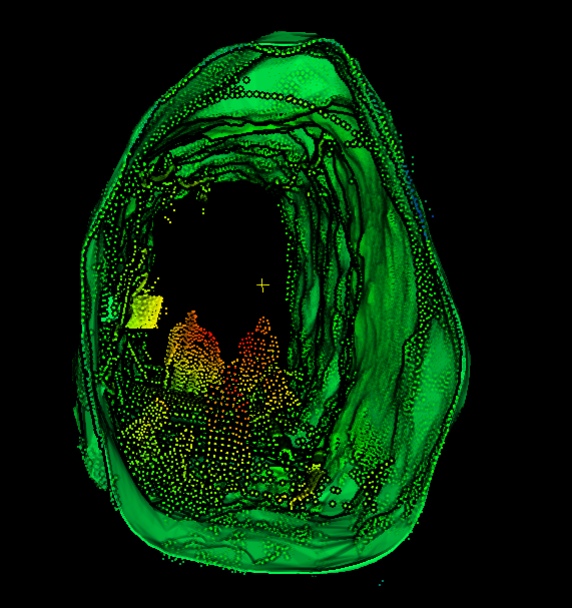

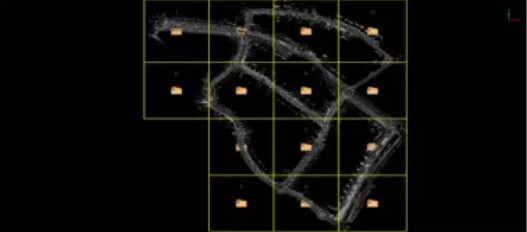

01. Aerial LiDAR 3D Mine Mapping for Open Pit Site

LiAir series products have obvious advantages in information extraction in terms of vertical spatial structure. Combined with horizontal spatial data, they can monitor the ecological environment of open-pit mines in an all-round way. UAV LiDAR can also obtain detailed and accurate measurements from inaccessible upper mine stockpiles in underground mines, making it ideal for scanning large areas of ore stockpiles, or large structures such as mining facilities.

- Accurately follow terrain fluctuations to achieve higher flight, effectively solve the limitation of LiDAR measurement distance, and ensure the consistency of image resolution and LiDAR point cloud density.

- Built-in high-precision differential GNSS board, high-precision IMU module, using tightly coupled differential algorithm to achieve point cloud plane, elevation accuracy centimeter level, to meet the needs of engineering measurement.

- It supports an integrated software and hardware solution ranging from accurate 3D route planning, point cloud data acquisition, real-time flight monitoring to point cloud trajectory calculation, flight band adjustment to standard point cloud result output.

- Seamlessly connect to point cloud processing software to quickly generate standard terrain results. The output standard point cloud can be directly entered into LiDAR360 point cloud data processing software. After automatic filtering algorithm and a small amount of manual editing, the output of standard terrain results can be completed, avoiding the cumbersome process in the middle. loss of precision.

- Laser scanning to obtain 3D point cloud models of open pit mining sites; digital terrain results such as DSM/DEM/DOM/DLG are generated.

- Using the LiAir lidar 3D scanning system to quickly obtain high-precision point clouds of ground objects, it has good maneuverability, flexibility and safety. It is a low-cost and high-efficiency stockpile volume measurement solution.

- Simultaneous acquisition of image data enables intuitive identification and management to understand the actual mining status of the mine

UAV LiDAR Payloads for 3D mine scanner

-

Entry Level drone LiDAR

LiAir X3 + LiGeo Software and Camera – Global Shipping – Free Software Included

Read MoreRated 0 out of 5

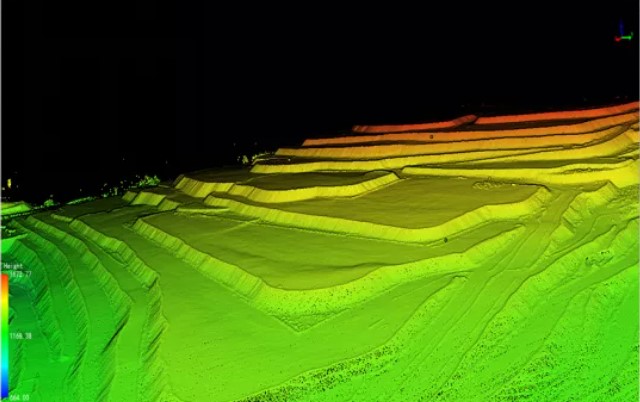

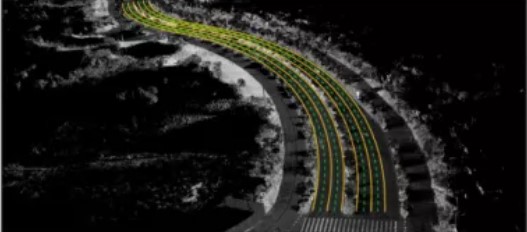

02. SLAM LiDAR Scanning system for Scanning Mine Tunnels

GVI SLAM LiDAR Scanners, such as LiBackpack DGC50, C50 and LiGrip, are self-developed LiDAR 3D mine scanners. They combine lidar and synchronous positioning and map construction technology to obtain high-precision 3D point cloud data of the surrounding environment in real time without GNSS. It is especially suitable for underground mines measurement work in harsh environments.

- The SLAM lidar scanning system supports both carrying and hand-held modes. The carrying method is convenient and comfortable, and the hand-held method is more flexible. It can be hand-held, can be hung on a vehicle, can be installed on an extension pole or a remote-controlled crawler, and is the best choice for roadway scanning.

- Data is displayed in real time on mobile terminals such as mobile phones and tablets; it supports wireless/wired viewing of data; data transmission is stable, and supports online closed-loop and closed-loop optimization. After scanning, the collected point cloud data and motion trajectories can be exported.

- The SLAM algorithm is stable and accurate: DGC50 adopts the leading SLAM algorithm, which can well adapt to the working environment with few roadway features and features, and effectively guarantee the data accuracy.

- Real-time solution: After the field measurement is completed, the initial point cloud data can be previewed and viewed in LiFuser-BP, and data preprocessing such as geographic coordinate conversion, noise filtering, and point cloud sampling is completed, which greatly simplifies the tedious operation of point cloud data analysis.

SLAM 3D LiDAR Scanning Products for Underground Mining Applications

Application for underground mine site

- The three-dimensional laser scanner is used to scan and detect the underground tunnel of the coal mine, and a three-dimensional model is established according to the scanning results. All data and models are with coordinates.

- Real-time spatial location information collection of mining face.

- Identify the roadway rock mass structure surface based on the point cloud, extract and analyze the inclination angle, inclination, trace length, spacing, etc. of the structure surface.

LiPod large space 3D laser scanner for mining Industry

Product Introduction

LiPod large space scanner is a new series of products launched by GVI. The product adopts simple style design, compact body and easy to carry. It integrates laser scanning, image acquisition, and GNSS coordinate acquisition, and does not require target features. Data can be collected quickly in a short period of time.

- The main unit is small in size and weighs only 3.0kg. It has an aluminum alloy shell and is equipped with a carbon fiber tripod, which makes the device more flexible to operate.

- Using high-precision dual-axis compensator, it has a larger compensation range, and does not need to be strictly leveled every time during scanning, and the operation is more convenient.

- It integrates various sensors such as cameras and electronic compasses, has a variety of data types, and seamlessly matches various data at the same time, and the data information is more abundant.

- The device is connected by WIFI hotspot, no need to connect cables, the operation is more flexible, the scanned data can be displayed on the handheld device in real time, and the operation is more intuitive.

Application for mining industry

- Open-pit mine slope monitoring: monitor the horizontal and vertical displacement, cracks, and dislocations of the surface; the deformation of the deep part of the slope and the deformation of the supporting structure.

- Roadway deformation monitoring: roadway deformation, gangway, floor drum, horizontal and vertical displacement of ground rails.

- Coal volume calculation: coal bunker coal volume calculation, real-time calculation of main transport belt coal volume.

- The instrument panel, switches and other facility components in the 3D model are accurately restored.

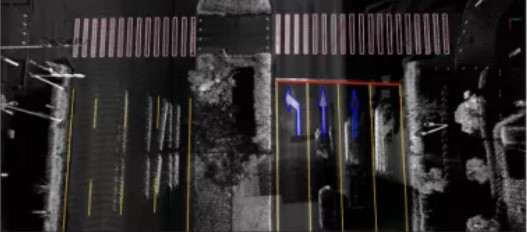

LiDAR360 MLS feature extraction and thematic map software for mine Scanning Software

Introduction

LiDAR360 MLS is a software for feature extraction and thematic map production independently developed by GVI. It uses automated and semi-automated operations to vectorize thematic data. It can be connected to a variety of GIS platforms. It can be widely used in the fields of precision map production, highway survey and design, reconstruction and expansion, digital city construction, and digital garden census, which will help to improve the level of urban informatization construction and management.

-

LiDAR Point Cloud Processing Software

LiDAR360 MLS Mobile/Handheld LiDAR Point Cloud Processing Software – 1 Year Subscription

US$4,890.00 Excl. GST/VAT Add to cartRated 0 out of 5

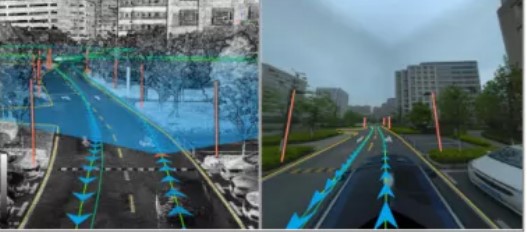

Support unmanned mining vehicles to achieve efficient transportation

The mining environment is complex, the working conditions are harsh and the risk factor is high. Solving the transportation problem in the mining area is directly related to the mining efficiency of the mining area. The relatively closed mining area is one of the most likely scenarios for unmanned driving. On the one hand, unmanned driving can reduce safety accidents in the mining area, on the other hand, it can reduce the cost of drivers. Therefore, the location calibration of the unmanned mining truck and the drawing of the base map of the mining area have become the top priority.

Lidar has the advantages of high measurement accuracy and wide detection range. 3D Lidar is often used to make the initial map template for high-precision maps, that is, point cloud maps. It can provide prior map information for autonomous vehicles. It plays an important role in positioning, environment perception, path planning and simulation experiments.

The unmanned driving system in the mining area is a cloud-based network-connected autonomous driving integrated solution with functions such as operation management, online status monitoring, and emergency driving safety takeover. Lidar technology, as an important part of it, has received more and more attention and attention.

LiDAR360 Mining Module - Mine Scanning software

Introduction

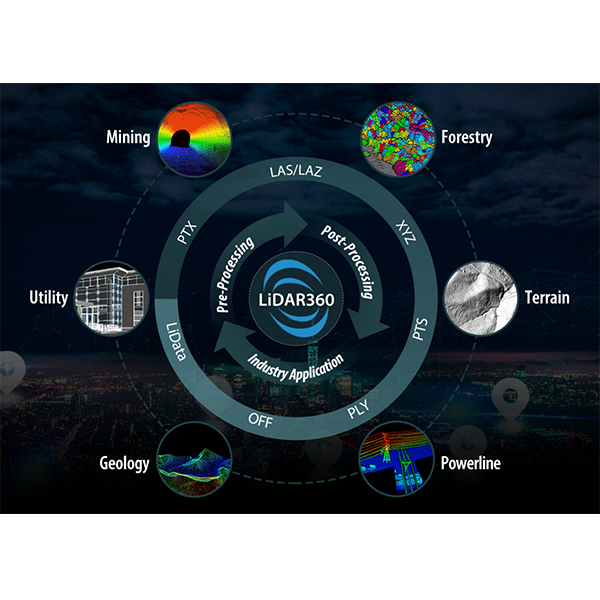

LiDAR360 was born in 2013. It is a professional processing platform for massive LiDAR point cloud data independently developed by GVI. This software provides professional point cloud data processing modules and rich data management tools, supplemented by AI and machine learning, which can efficiently and accurately edit and analyze airborne, vehicle-mounted, ground-based, handheld and other multi-acquisition platforms with different formats and types point cloud data, and generate professional geospatial products for many industries, forming convenient and efficient industry solutions.

-

LiDAR Point Cloud Processing Software

LiDAR360 Aerial LiDAR Point Cloud Processing & Analyzing Software – 1 Year Subscription

US$4,300.00 Excl. GST/VAT Add to cartRated 0 out of 5

LiDAR360 Mining Module - Mine Scanning Software

Based on the real-time 3D LiDAR point cloud data of multi-platform mines such as airborne and backpack, LiDAR360 measurement module and terrain analysis module can realize the detection of mining path change in open-pit mines, quantitative analysis of mining workload, and auxiliary decision-making of mining planning; at the same time, underground mines can be realized. The roadway is regularly monitored and analyzed to assist in accident early warning and decision-making.

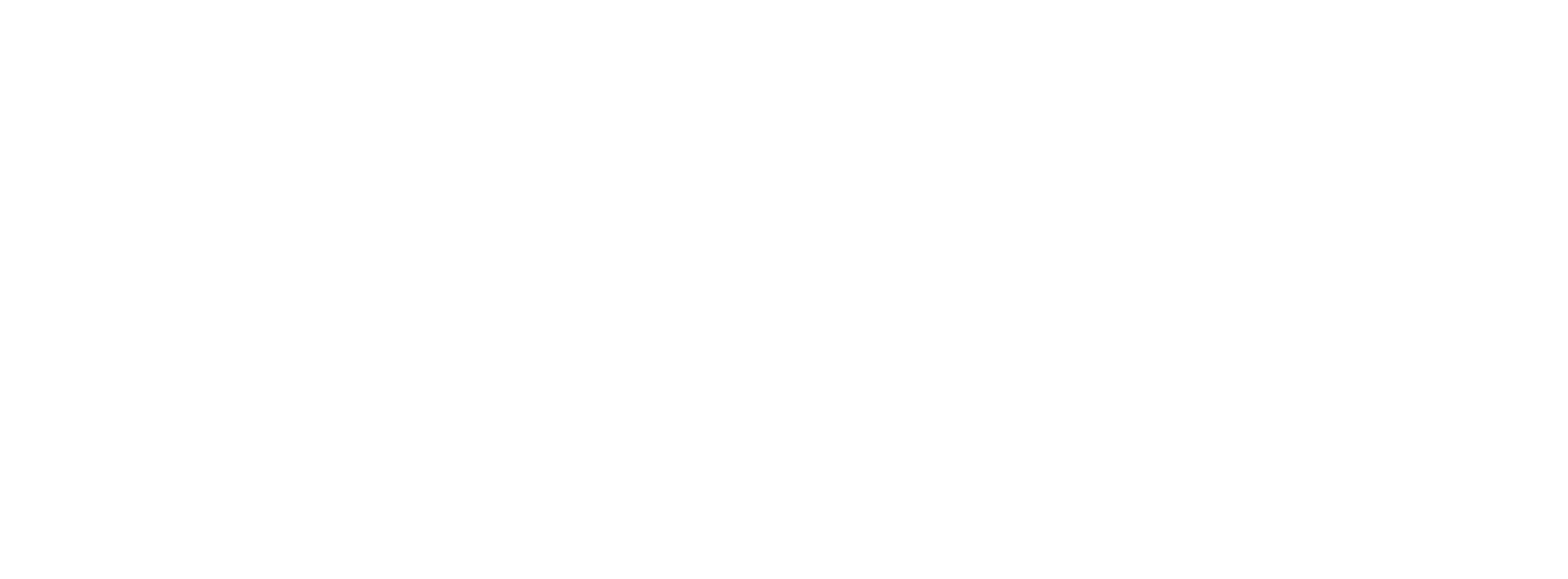

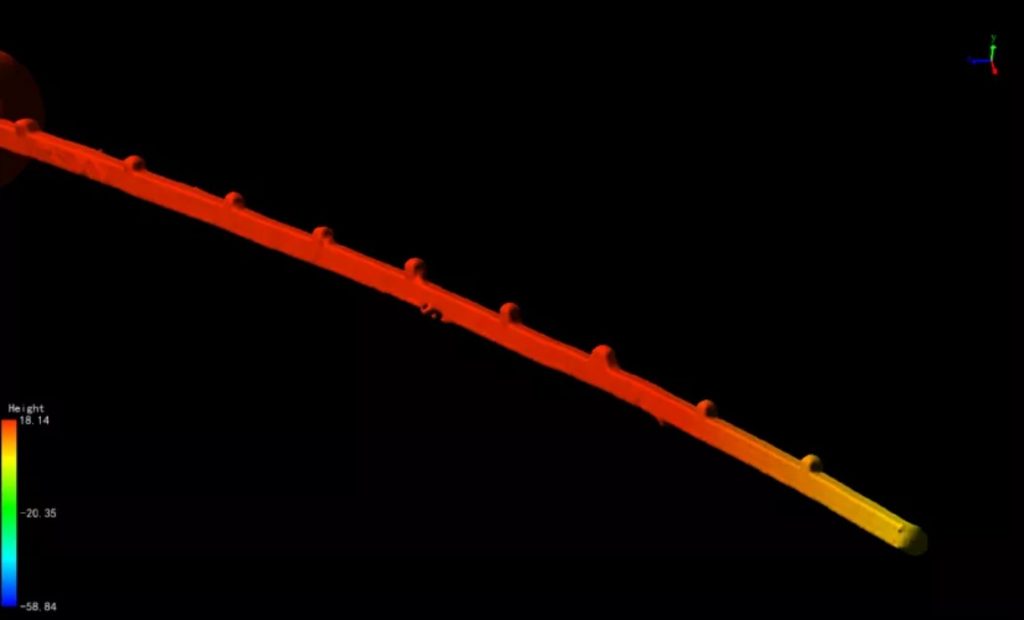

- Roadway Section Analysis

Based on the point cloud data, a high-fidelity 3D model of the roadway is generated in LiDAR360, and the difference values of the standard (reference) section and the scanned (point cloud-derived) section are compared to monitor the roadway deformation.

- Mine pile volume measurement

The three-dimensional laser scanning system is used to observe the deposits and quickly obtain the three-dimensional coordinates of a large number of ore surface points. The software can accurately calculate the volume of the ore pile according to the principle of calculus.

- 3D modeling

It is used to process point cloud data such as mines, tunnels, and roadways. Through slice filtering technology, the noise information on the scanned surface is removed. Combined with triangulation or Poisson modeling, it can quickly obtain a smooth and consistent triangulation model of roadway data.