Powerline, Transmission Line & Substation Inspection with Drone and Mobile LiDAR Scanners

Powerline, transmission line and substation inspection with Drone and Terrestrial LiDAR is an effective way to identify potential issues before they impact your electrical infrastructure. LiDAR sensors can capture multiple echoes and provide accurate location and coordinates of electrical facilities, ground objects, and vegetation. Using LiDAR can also improve inspection efficiency.

Benefits for LiDAR Transmission Line & Substation Inspection

Powerline, transmission line and substation inspection is a necessary step in power distribution infrastructure maintenance. It prevents outages by monitoring the infrastructure and identifying issues that could compromise the integrity of power lines. Power outages cause massive economic losses and threaten the natural ecosystem. In addition to short circuits, powerline inspection can also detect other power distribution anomalies that could threaten power quality.

Aerial systems equipped with LiDAR capture data from target areas of powerline, transmission line and substation infrastructure. These data are processed to create a 3D map & model that shows the distances between powerlines and surrounding vegetation. This mapping data allows operators to focus their efforts on the areas that pose the greatest threat to power lines. Because LiDAR is fast and accurate, operators can use it to detect sagging wires, dangerous trees, and other potential hazards.

Aerial mapping is another option for powerline inspection that is cost-effective and saves time. An aerial survey can map up to 50 km of transmission lines in a single day, saving grid operators time on the ground and reducing labor costs by up to 50%. Aerial mapping uses a full-frame camera and in-house algorithms to produce lidar-quality data.

Lidar technology has the ability to visualize powerlines and identify problems that can affect their safety. It is used to inspect high-voltage powerlines and detect any problems before they cause damage to the electrical network. It can also detect the presence of vegetation that could pose a risk to power lines. The use of lidar technology can help utility companies to minimize the costs and risks of power line inspection.

LiDAR power line inspection can help grid operators to map wire profiles, which is particularly important in regions with high traffic density and large machinery movement. These inspections also help grid operators to react to potential problems before they cause damage to the network. A single powerline span can be inspected in as little as ten minutes with a single technician or two.

Drones equipped with LiDAR can survey target areas and generate a 3D map that shows the distance between powerlines and vegetation. This allows operators to avoid clearing large areas and focus their efforts on the most dangerous areas. LiDAR is also used to detect sagging wires and potential tree fall.

LiDAR System for Powerline Inspection

LiDAR Solutions Australia possesses backpack, vehicle-mounted, and drone-based LiDAR scanning systems capable of operating under diverse site conditions. These systems are designed to meet efficiency, environmental, health, and safety (EHS), and data quality standards.

This flexibility allows for tailored data collection strategies that adapt to specific project needs, ensuring that all operations are conducted with optimal precision and safety. The various deployment options provided by LiDAR Solutions Australia enable comprehensive coverage and high-resolution data acquisition, essential for detailed analysis and decision-making in a range of industries.

Site Photos:

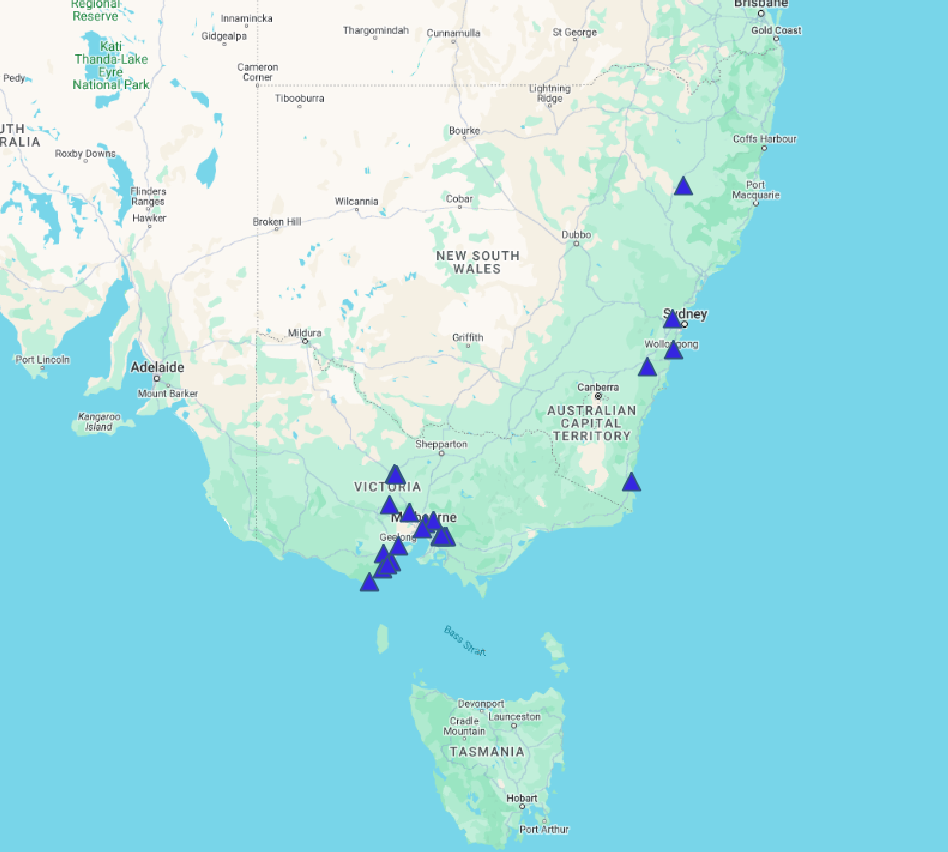

Our Project Experience for LiDAR Powerline & Substation Inspection & Survey

LiDAR Solutions Australia, a pioneering firm in light detection and ranging technology, has successfully completed over 20 projects throughout Victoria and New South Wales. The company employs a variety of LiDAR systems, including terrestrial, vehicle-mounted, and drone-mounted technologies. This versatile approach allows them to deliver precise, high-resolution 3D models across diverse environments, enhancing planning and decision-making processes in various industries.

Why Our Customers Choose Us?

- End to End Solutions and services

- Multi terrestrial and aerial LiDAR system can be used to meet the various site conditions

- Deliver the precise data and report as per your requirements

- Always on time and on budget

- We go extra miles

Contact Us

LiDAR Software for Powerline Inspection

LiAcquire - Airborne LiDAR Control Software

- Control laser scanners, cameras and POS system data collection.

- Monitor the collection process, including the size of the collected data, GPS satellite status, IMU status, etc.

- Supports strip cutting, point cloud calculation, point cloud measurement, and data playback.

- Support starting the RTK of the device to solve the point cloud data in real time.

LiGeoreference - Drone LiDAR point cloud solution software

- It supports multiple types of laser data, various combined navigation data and visible light image data.

Guided operation, - Support parameter memory, export and import, easy parameter configuration.

- High-efficiency calculation speed, supports multiple output results.

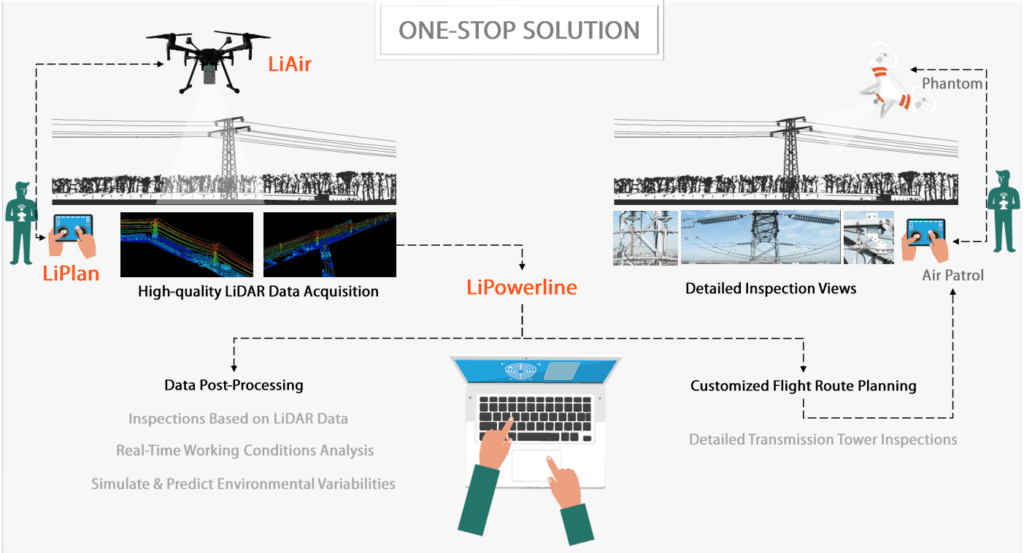

LiPowerline - laser LiDAR power line inspection software

Green Valley International is a leading provider of turnkey lidar surveying systems and 3d mapping technologies. Lipowerline processed a total of fifteen thousand kilometres of data live power line, provides data post-processing and analysis tools for working with lidar point clouds and high-resolution imagery.

Through the processing and analysis of massive point cloud data, LiPowerline can quickly and accurately extract the information of dangerous targets in the power channel, and provide analysis and prediction for the safe operation of power under comprehensive simulated working conditions.

- Visual editing of terabyte point cloud data.

- Machine Learning Point Cloud Classification.

- Accurately calculate the amount of dangerous trees to be removed.

- Simulated working conditions, scientific early warning.

Key Features of LiPowerline

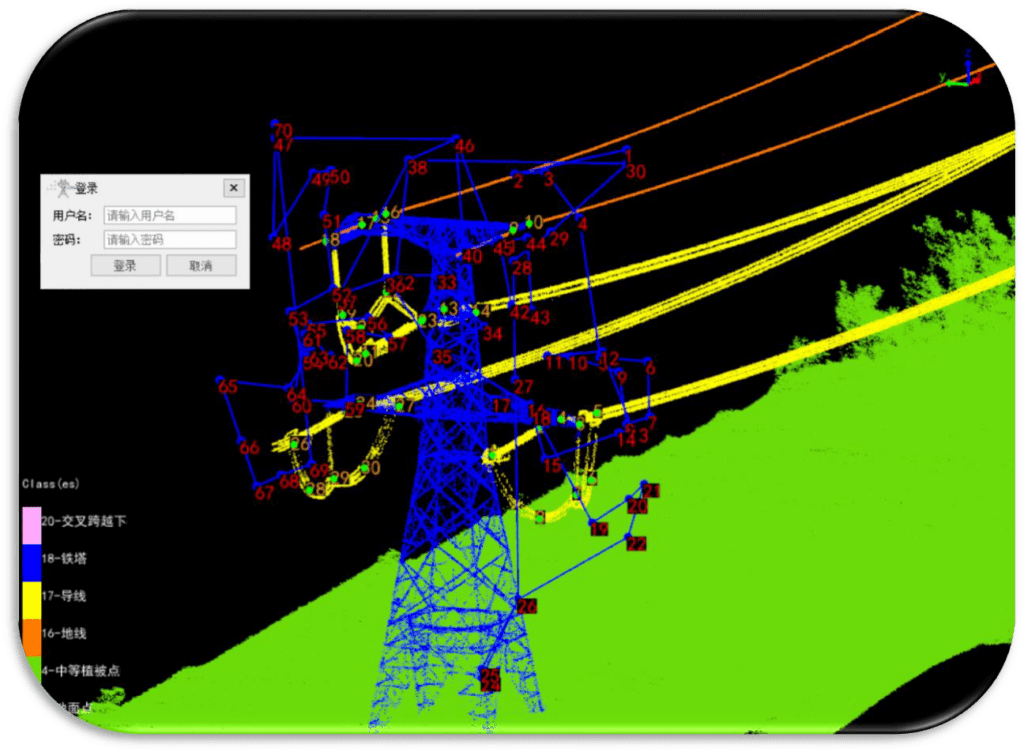

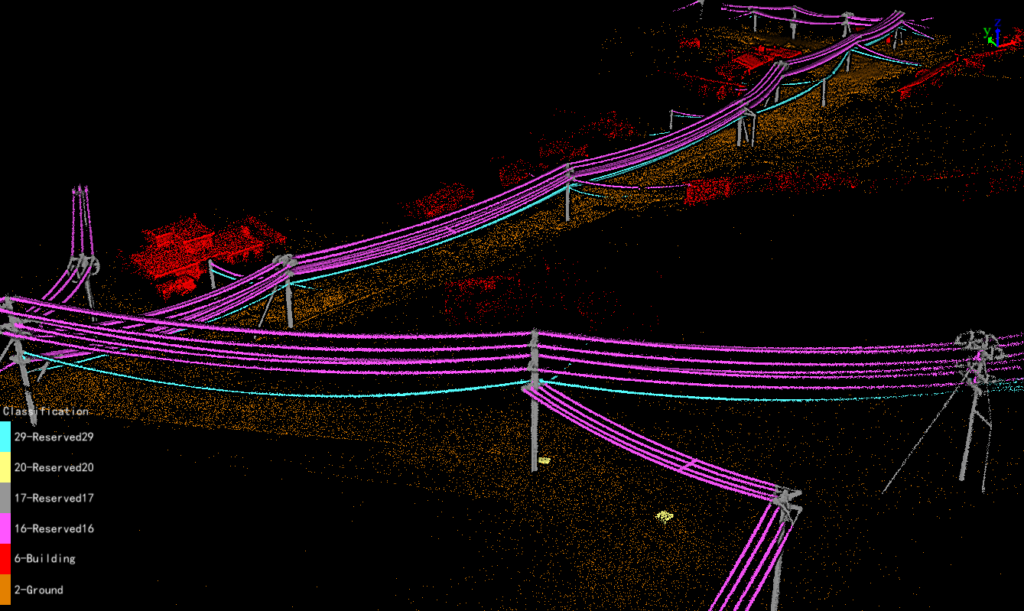

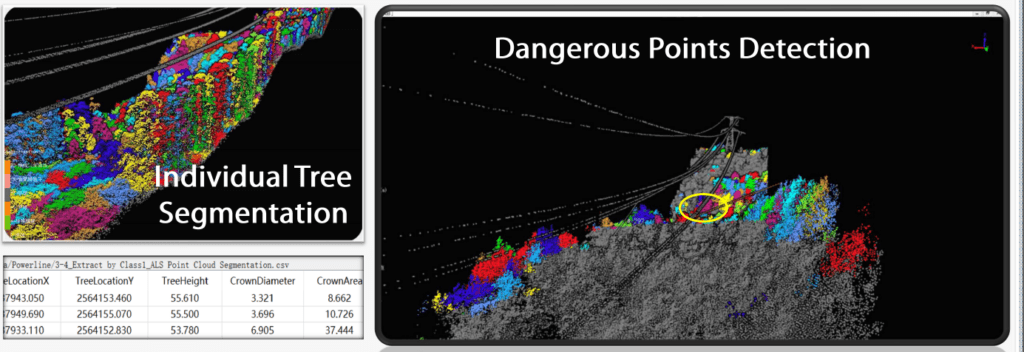

Powerline Inspection LiDAR Point Cloud Classification and Dangerous Points Dection

It can automatically classify the transmission tower and power line points with its deep learning algorithms. What’s more the software provides both 2d and 3d profile tools to inspect and edit classification results. Lipowerline is also able to perform real-time working condition of analysis, detect danger points, and measure powerline clearances and spec scissor crossings, monitor individual trees and carry out tree fall analyses.

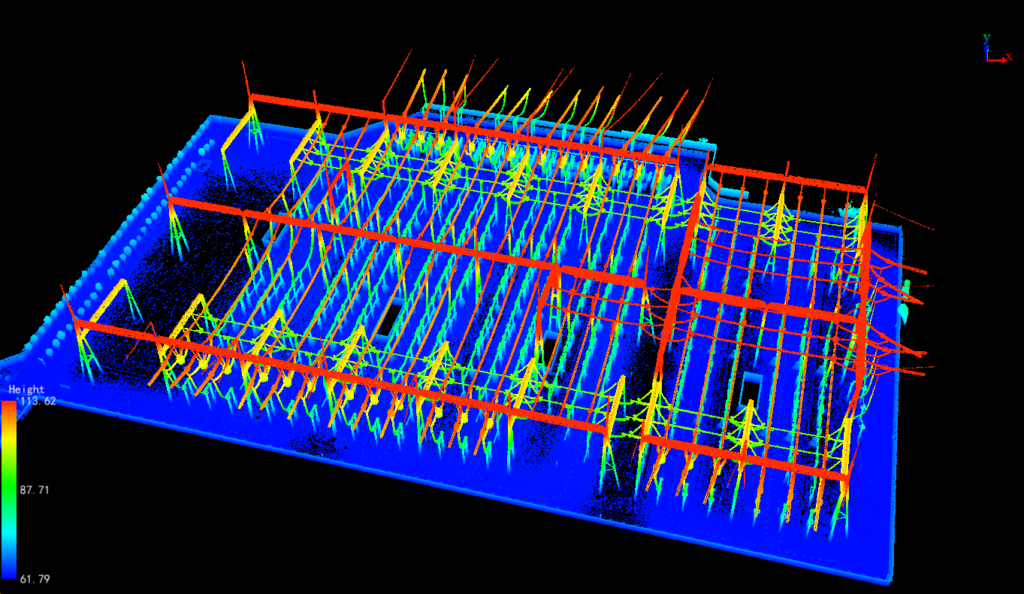

Transmission Line LiDAR Point Cloud Data Analysis

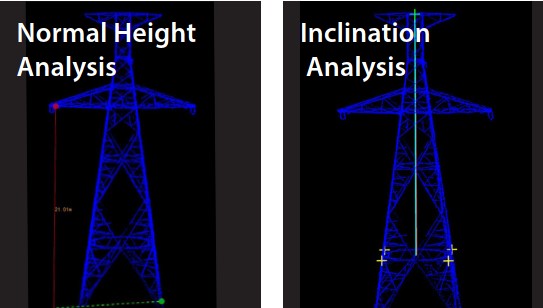

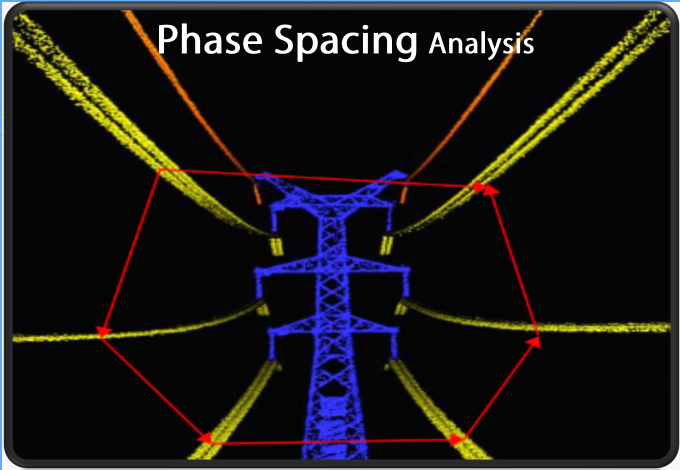

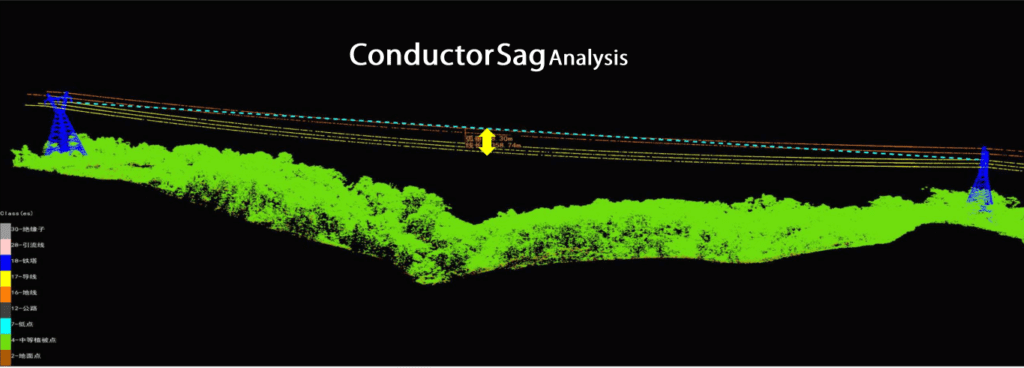

Interactive point cloud vectorization tools included in Lipowerline allow for the creation of 3d models, but then serve as inputs to simulations that output descriptions of the impact user defined temperature wind and ice loadings have on the Sagan’s way of specific conductor types. The vectorized point cloud model is created in Lipowerline can also be used when analyzing sag and phase spacing of powerlines to monitor the status of individual wires and conductors or measure tower inclinations and height differences between cross arms of electrical transmission towers.

Customized Flight Planning

Lipowerline also contains an easy-to-use tool set for constructing UAV flight routes from previously collected point cloud data. This unique software feature is designed to meet the flight planning needs of pilots and drone operators who must inspect specific electrical infrastructure assets, such as transmission towers and conductors for signs of the damage or failure. Around these images can capture key asset components targeted for an inspection such as pylons insulators power line fittings.