Automated Truck Load Monitoring & Scanning LiDAR System

Accurate load monitoring is essential for safety and efficiency in bulk transportation. While traditional methods like manual measurements are slow and error-prone, LiDAR (Light Detection and Ranging) technology offers a superior, automated solution. This blog post explores the technical implementation of a LiDAR system for real-time bulk truck load monitoring.

Key Challenges in Truck Load Monitoring

Harsh On-Site Conditions: Dust, noise, and adverse weather reduce loader operator visibility and precision, leading to inefficient and inaccurate loading.

Human Operational Error: Unskilled operation results in uneven load distribution, material spillage, and overloading, compromising safety, efficiency, and material integrity.

Inefficient Resource Use: Manual monitoring is labor-intensive and costly. Poor visibility into tall carriages causes inaccurate loads (under/over), leading to resource waste and higher transportation expenses.

Contact Us

Automated Truck Load Monitoring & Scanning LiDAR System - Site photos

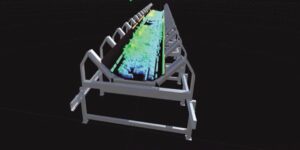

The fixed LiDAR stockpile measurement system can be installed on the cranes either indoor or outdoor. Its installation location needs to be assessed according to the area to be covered underneath the crane.

In most case, only 1 LiDAR sensor is required on 1 crane, it can cover the whole area where the crane can move above, so it is very cost effective. However, the volume of the stockpiles can only be calculated after the crane is moved above the area, so its flexibility may be reduced.

the benefits to use LiDAR equipment to measure Truck Load volume

Safety

LiDAR is a non-contact measurement method, which means it can be used to measure truck volumes without the need for personnel to physically access the stockpile. This is especially important for stockpiles of hazardous materials or in dangerous locations.

Versatility

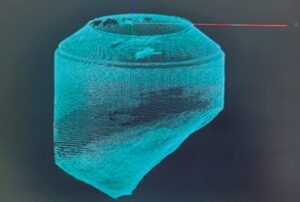

LiDAR can be used to measure truck bulk of various sizes and shapes.

High Accuracy

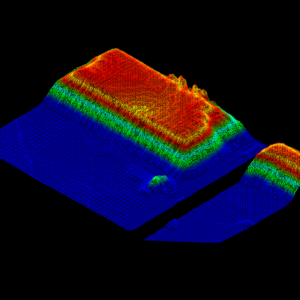

LiDAR provides highly accurate measurements, which is essential for inventory management and resource allocation. The precision of LiDAR can help companies avoid costly mistakes and make more informed decisions.

High Efficiency

LiDAR is a fast and efficient method for measuring truck load volumes. Traditional methods, such as manual surveying, can be time-consuming and labor-intensive. LiDAR, on the other hand, can quickly scan truck load and provide accurate volume measurements in a fraction of the time.

Data Analysis

The data collected by LiDAR can be easily integrated with other systems and used for further analysis. This can provide valuable insights into inventory management, resource allocation, and other aspects of operations.