LiDAR Conveyor Flow Monitoring: Flow, Deviation & Jam Analysis

how does liDAR conveyor flow monitoring system work

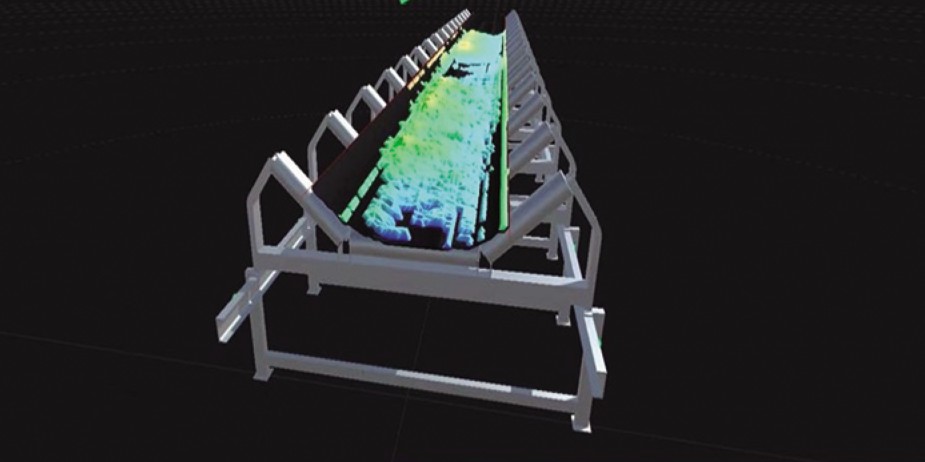

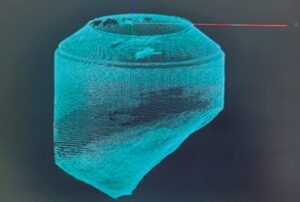

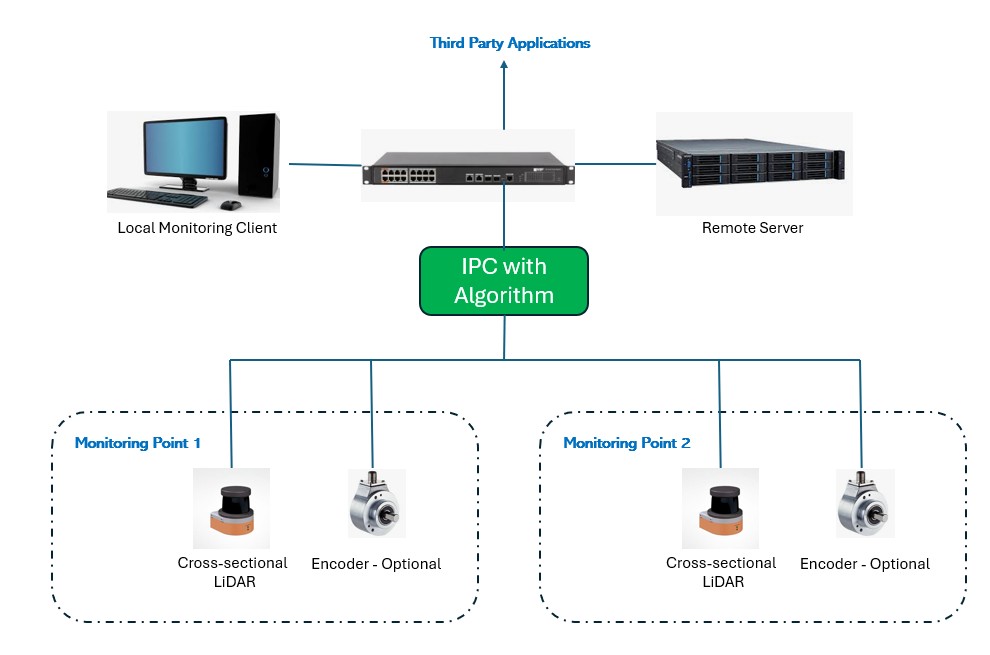

LiDAR conveyor monitoring systems use 2D or 3D laser sensors to scan materials on a conveyor belt, creating a real-time cross-sectional profile. By integrating live conveyor speed data from an encoder, an industrial computer (IPC) calculates the volumetric flow rate. The system can also compare data from the conveyor’s input and output points. This enables it to identify critical issues like flow deviations, jamming, and other potential faults in real-time, enhancing both operational efficiency and safety.

With the support of the local monitoring client and remote server, the operators can monitor the system locally or office based off-site. The system can also be integrated into the third party application via TCP/IP Modbus protocol.

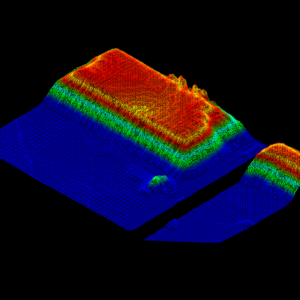

Except for measuring the stockpile volume, LiDAR point cloud data generated in different time can also be used to calculate the stockpile change as well as volume difference.

System Function

Real-time Belt Flow Monitoring

In mining and steel mill applications, belt conveyors operate at high speeds over long distances, creating a significant challenge for accurate flow measurement. However, obtaining this precise flow data is essential for effective material control and production guidance during critical processes like raw material loading, unloading, and production feeding.

Entry/Exit Flow Satistics

The cross-sectional flow profile collected at the entry and exit plus the conveyor speed enable the system to conduct entry/exit statistics.

Deviation and Jamming Warning

Powered by AI algorithm, the system can identify the risk of flow deviation and conveyor jamming from the LiDAR data.

Contact Us

LiDAR Conveyor Flow Monitoring system - Site installation and HMI